CRIPTOIDE

Our Mission

To supply the best-in-class automobile press hardened steel structure components, manufactured in a safe and environmentally friendly setting.

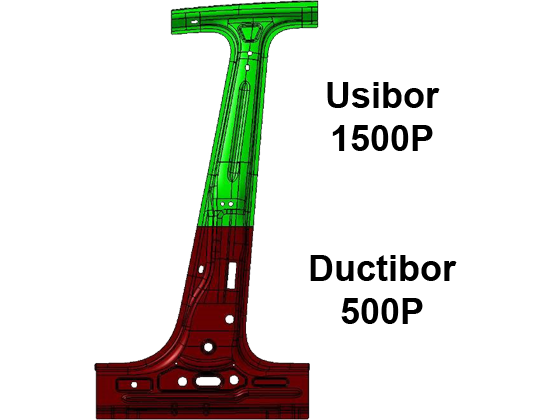

GNS Mexico as part of GNS group was conceived as the division specialized in the perfection of the Hot forming technology & process.

What makes GNS a unique company in the Automotive Stamped structure components industry is:

- The flexibility to work as a Tier 1 or Tier 2 in accordance to the OEM’s needs, due to our specialization in the Hot Forming process.

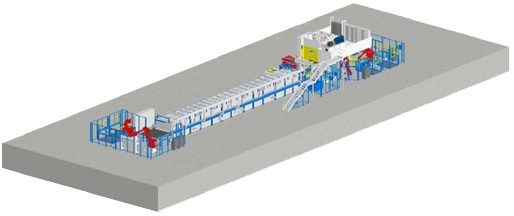

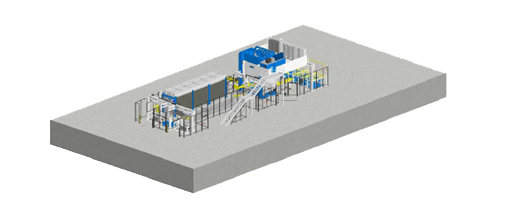

- The simplicity of our compact Hot Forming line layout, that allows us to add capacity in a smaller surface than competitors (4 to 1).

All of the above plus our tireless focus on continuous improvement makes GNS a “Solutions Company” for the automotive industry.